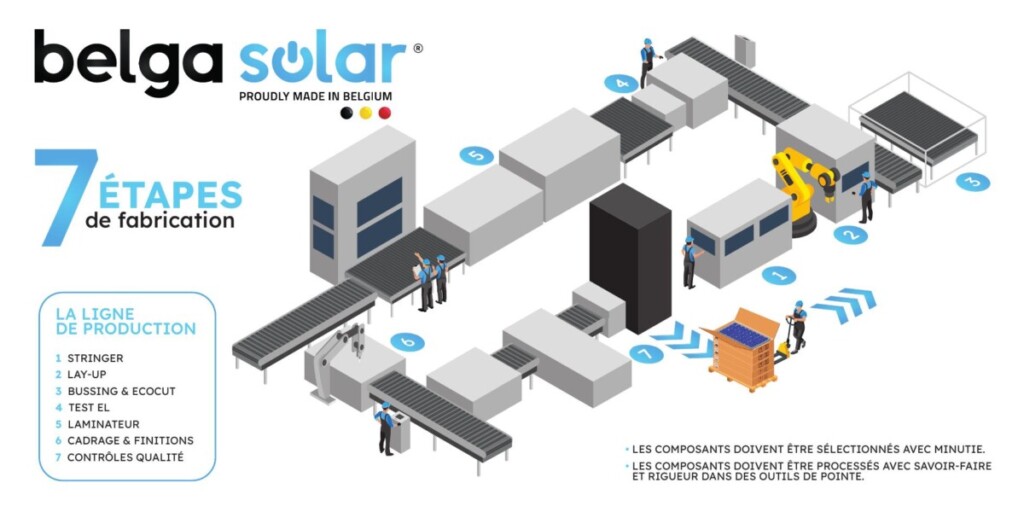

The manufacturing of a solar panel is a high-precision industrial process where every step plays a crucial role. From the laser cutting of the cells to the final quality checks, everything is designed to guarantee energy efficiency, durability, and safety. Let’s explore, step by step, the production line of a modern solar panel.

Careful Selection of Components

Even before production begins, the focus is on material selection.

All components are carefully sourced from reliable, specialized suppliers.

They are then processed with expertise and precision using state-of-the-art equipment. This upfront quality directly determines the performance of the finished solar module.

1. Stringer: Cutting and Assembling the Cells

The process starts with preparing the photovoltaic cells:

-

Cells are laser-cut to maximize efficiency.

-

They are assembled using copper ribbons coated with tin and silver, ensuring excellent conductivity.

-

Each cell is divided into 9 half-cells, making the panel lighter and easier to handle.

-

An integrated camera continuously monitors the process for quality assurance.

This step is critical: a single faulty solder joint can significantly reduce panel efficiency.

2. Lay-Up: Layer Stacking

The prepared strings are precisely positioned on anti-reflective tempered glass.

-

The quality of this glass is vital, as it directly impacts light absorption.

-

The cells are then covered with EVA (Ethylene-Vinyl Acetate), a transparent encapsulant that lets UV rays pass through while protecting the cells.

The Lay-Up process forms the core of the module, ensuring both light transmission and long-term durability.

3. Bussing & Ecocut: Electrical Connections and Protection

-

Bussing: Strings are interconnected using bus bars, creating a complete electrical circuit for efficient energy flow.

-

Ecocut: A second layer of EVA is added to block UV rays, followed by the application of the backsheet, a high-quality protective rear layer.

These steps secure both the panel’s electrical performance and its mechanical strength.

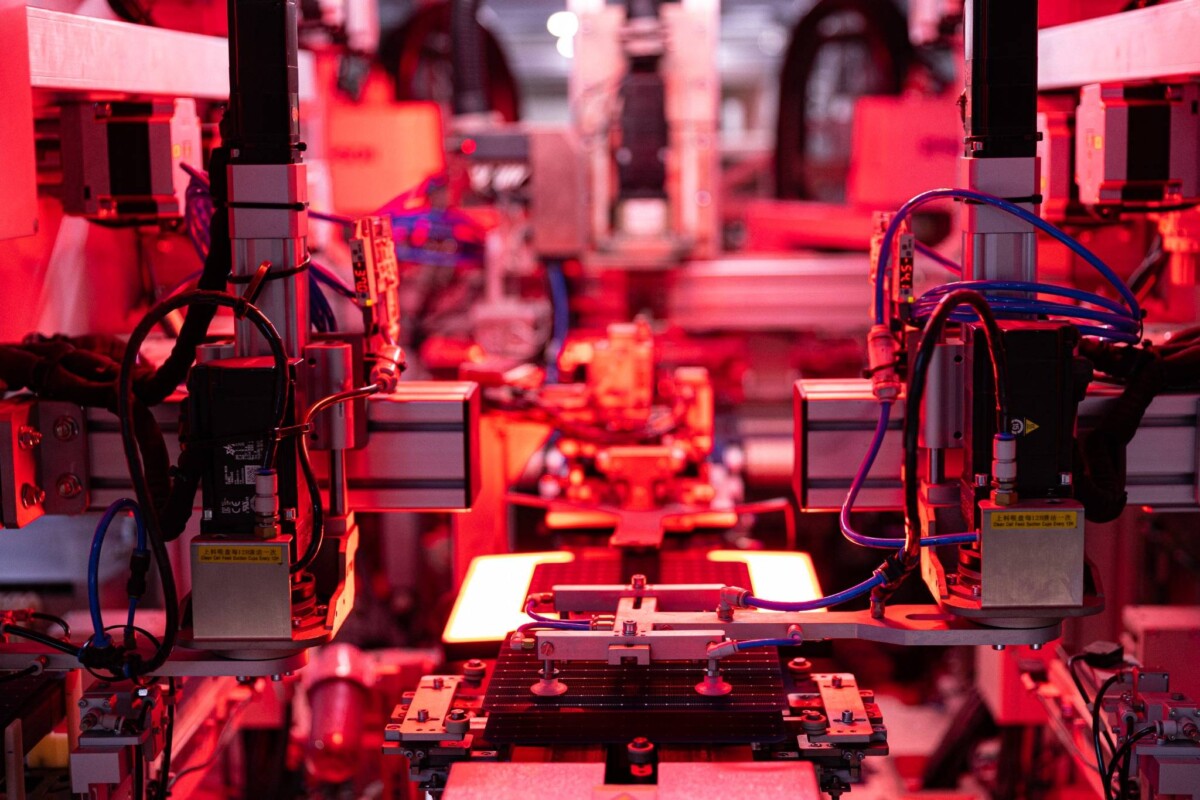

4. EL Test: Detecting Microcracks

Before final sealing, the panel undergoes an EL (Electroluminescence) test.

-

This inspection verifies soldering quality and reveals microcracks invisible to the human eye.

-

The test is enhanced with artificial intelligence, trained on the team’s extensive experience, making it more reliable.

Only flawless panels move on to the next stage.

5. Laminator: Encapsulation and Cooling

The panel then enters the laminator, a vacuum oven at high temperature.

-

The vacuum removes all air bubbles.

-

The heat melts and polymerizes the EVA, permanently encapsulating the cells.

After laminating, the panel undergoes a cooling phase, necessary for safe handling. This is followed by deburring, where excess resin is trimmed to ensure a neat finish.

6. Framing and Finishing

The laminated panel is reinforced with an aluminum frame, providing rigidity and making installation easier.

-

A junction box with connectors is fixed to the back, allowing current to flow out.

-

Potting material is added to insulate the connections and protect them from moisture.

This stage ensures both mechanical strength and electrical safety.

7. Quality Control and Traceability

Every solar panel undergoes 100% quality testing, with full traceability:

-

Flash Test: a daily calibrated light source measures key electrical parameters (power, voltage, current).

-

Electroluminescence: current injection reveals hidden internal defects.

-

Visual Inspection: operators check the panel’s aesthetics and finishing.

These rigorous tests ensure compliance with international standards and guarantee decades of reliable green energy production.

Precision and Expertise for Sustainable Energy

The solar panel production line is much more than simple assembly. It is a combination of technical expertise, advanced machinery, and strict quality control. Thanks to this approach, solar panels consistently deliver high performance and long-lasting reliability for more than 25 years.